I-AM finishing SurfPRO (Polymers)

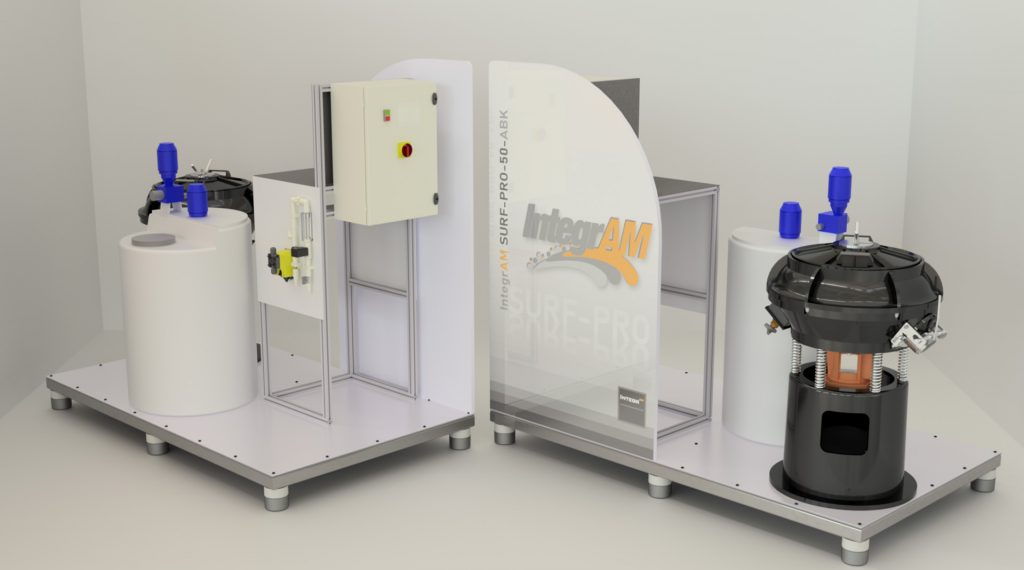

A portfolio of exclusive solutions, dedicated to Additive Manufacturing, dedicated to the finishing of polymers and composites. The Surf PRO line of finishing systems, available on technological pallets with or without cabin that can be opened on the sides where access is required, a program divided into at least 4 technological lines, available in at least two capacities, respectively of 50 or 120 liters in volume.

SurfPRO BS

The SurfPRO BS line of machines – Basic Standard – allows to operate wet finishing processes or surface roughness attenuation;

SurfPRO MF

The SurfPRO MF line of machines allows to operate MicroFLUID (Patent pending – I) multitasking processes – the use of this technology allows to use a single machine and a single finishing media instead of multiple machines with multiple types of media, which vary from very abrasive, to medium abrasive to polishing, thanks to the use of special products that can be automatically dosed.

SurfPRO SD

The SurfPRO SD machine line allows for steam dyeing processes with very low colour consumption that is unattainable in traditional processes (Techno Surface Patent) – the use of this technology allows for the use of a single machine for different and multipurpose uses.

I-AM finishing SurfPRO (Metals)

A portfolio of exclusive solutions, dedicated to Additive Manufacturing, dedicated to the finishing of metals. The Surf PRO line of finishing systems, available on technological pallets with or without cabin that can be opened on the sides where access is required, a program divided into at least 4 technological lines, available in at least two capacities, respectively of 50 or 120 liters in volume.

SurfPRO BS

The SurfPRO BS line of machines – Basic Standard – allows to operate wet finishing processes or surface roughness attenuation;

SurfPRO MF

The SurfPRO MF line of machines allows to operate MicroFLUID (Patent pending – I) multitasking processes – the use of this technology allows to use a single machine and a single finishing media instead of multiple machines with multiple types of media, which vary from very abrasive, to medium abrasive to polishing, thanks to the use of special products that can be automatically dosed.

SurfPRO ABK

The SurfPRO ABK line of machines – Abrakem – allows to operate wet Abrakem finishing processes or surface roughness attenuation;

SurfPRO WBT

The SurfPRO WetBLAST WBT machine line allows for roughness reduction processes – even to the point of obtaining hydrophobic surfaces – with the aid of steam, including wet sandblasting with metal surface sanitization processes (Patented) – the use of this technology allows for the resolution of critical aspects in the medical, dental, food and related sectors.

I-AM VibroBLAST Air

The multidisciplinary VibroBLAST technology represents a real “R-Evolution” in the field of sandblasting and shot blasting of surfaces. This is possible partly thanks to the combination of vibratory finishing and sandblasting / shot blasting techniques, partly to a range of “elastic” or “resilient” QF vibratory finishing media, capable of acting as a vector of the three-dimensional movement of the treated components, exposing them several times in different positions at the blasting source. On the other hand, the same QF media are able to absorb shocks and protect components during the surface preparation processes, offering a new alternative approach to manual techniques, a much more delicate and respectful environment than rotary-barrel or rotary-belt and a much cheaper alternative to using robotic solutions.

On the side, the most technologically advanced version, the result of improvements between 2019 and 2021, of the best-selling VibroBLAST machine, the VBA-DP-120-SN-EX with Atex filter aspirator (Internal Zone 20), with sandblasting nozzle in SN (Side Nozzle) version applied to the vertex of the upper corolla of the polyurethane tank.z

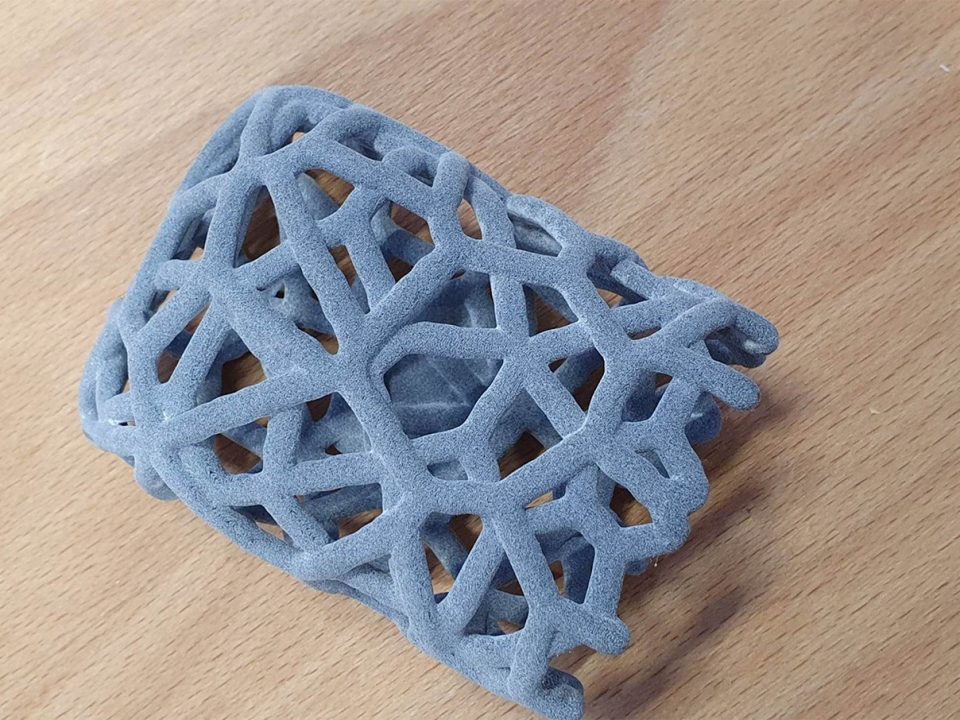

The VibroBLAST technology allows excellent preparation of the surfaces of components printed in SLS or MJF, for example, as in the photo, by removing the additive dust from the innermost and nested areas; Photo courtesy of the HALL 32 laboratories of Clermont Ferrand – France

VibroBLAST technology allows excellent preparation of the surfaces of components printed in SLS or MJF, for example, as in the photo, by removing additive dust from flat surfaces with homogeneous results; Photo courtesy of the HALL 32 laboratories of Clermont Ferrand – France

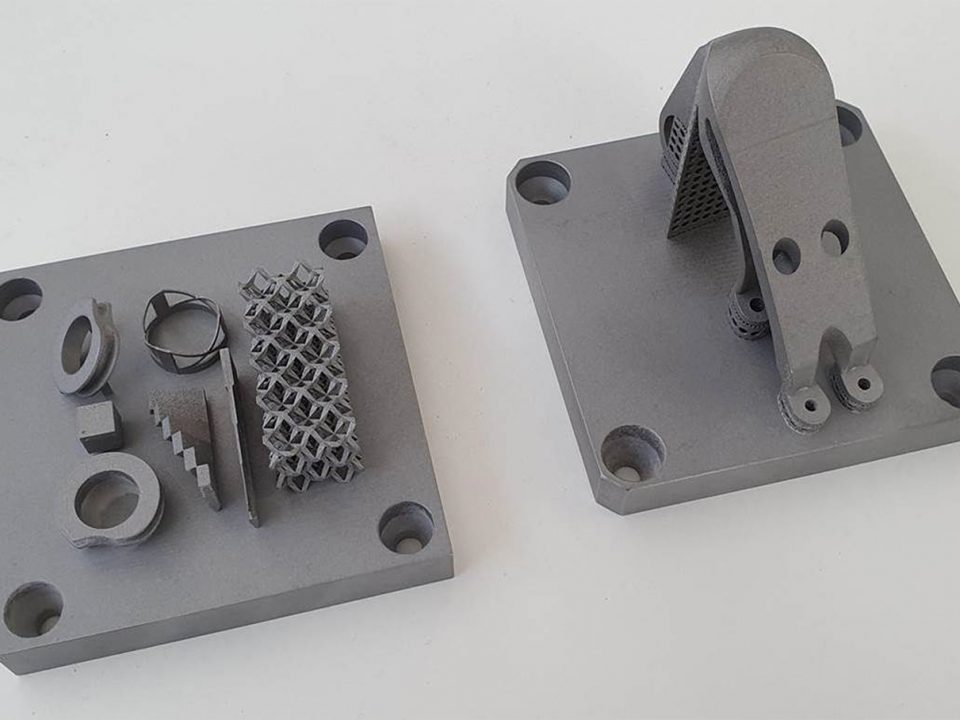

VibroBLAST technology allows excellent preparation of the metal surfaces of components printed in SLM or DMLS, for example, as in the photo, by removing additive dust from flat surfaces with homogeneous results and from 100% nested areas. Photo courtesy of the workshops of HALL 32 in Clermont Ferrand – France

I-AM Post Process & Finishing DCK

The multidisciplinary VibroBLAST DCK technology represents a real “R-Evolution” for the AM sector of polymers, generated with both SLS and MJF as well as in the field of sandblasting and shot blasting of surfaces. A multitasking system able to deconstruct a cake, recover the non-sintered additive powders, subject them to vibroselection and recover the reusable ones again, then proceed to an automatic VibroBLAST vibro-blasting process on the sintered components, so as to prepare the surfaces to be clean and free of cohesive additive powders.

IntegrAM VibroBLAST – DCK automatic systems for Unpacking, Decaking, destructuring of the build, recovery and screening of additive powders, surface preparation with vibro-blasting, the result of three international patent applications;

IntegrAM’s VBA-DCK systems are the only ones in the world to deal with polymers from SLS or MJF from the load of the build to the component ready for subsequent processes, with the highest level of automation and reduction of operating costs and with perfectly prepared surfaces, recovered and selected additive powders (where required).

Blasting cabinets BlastOK!

BlastOK is the new line of compressed air sandblasting cabinets, designed for every type of application in the Additive Manufacturing and 3D printing sector.

While with the innovative VibroBLAST technology you can treat batches of medium-small or small size components, with BlastOK machines you can sandblast both large-sized components or, equally, medium-sized but particularly heavy components or those that would require investing in large-sized VibroBLAST solutions without having sufficient numbers for the return on investment.